Choosing the right CO2 laser is perhaps the single most critical investment a clinic can make in advanced skin resurfacing. CO2 laser technology is divided into two major camps: the traditional Glass Tube (DC) laser and the modern Metal RF Tube (Radiofrequency) laser.

While both emit the 10,600 nm wavelength, the mechanism of energy delivery fundamentally dictates the results, downtime, and safety profile. For medical aesthetics and high-precision fractional treatments, the Metal RF Tube laser is universally recognized as the superior technology.

Below is a detailed breakdown of why the RF-excited metal tube has become the industry’s gold standard.

The Core Difference of Metal RF Tube & Glass Tube

The critical difference lies in how the CO2 gas is excited to produce the laser beam: Direct Current (DC) vs. Radiofrequency (RF).

| Feature | Glass Tube CO₂ Laser (DC Excitation) | Metal RF Tube CO₂ Laser (RF Excitation) |

|---|---|---|

| Excitation Method | Direct Current (DC) High Voltage | Radiofrequency (RF) Electromagnetic Field |

| Beam Quality | Good, but prone to drift due to heat. | Excellent (TEM00 Mode); beam spot is more stable and smaller. |

| Pulse Quality | Continuous Wave (CW) or Long Pulse. Difficult to produce extremely short, high-power pulses. | UltraPulse / SuperPulse capabilities, featuring very high peak power. |

| Cooling Method | Water Cooling is mandatory. | Typically Air-cooled or Closed-Loop Water Cooled. |

| Size & Structure | Longer, heavier, and uses an open gas system (prone to leakage). | Compact, lightweight, and uses a sealed gas system (rechargeable). |

| Lifespan & Maintenance | Shorter (~ 1,000 to 3,000 hours); gas degrades quickly, requiring full tube replacement. | Extremely long (~ 10,000 to 45,000 hours); can be refilled with gas, leading to lower long-term maintenance costs. |

| Equipment Cost | Low (Often used for industrial cutting or basic aesthetics). | High (Standard for high-end medical and aesthetic applications). |

| Aesthetic Applications | Suitable only for basic vaporization, cutting, or low-power resurfacing. | Fractional Resurfacing, Scar Revision, Deep Wrinkle Treatment. |

Why the Metal RF Tube is Better for Aesthetics

The dominance of the metal RF tube in the medical aesthetic field is primarily due to its ability to generate high-quality, controlled pulses. The effectiveness of a CO2 laser is determined by its ability to deliver energy to the tissue in an extremely short time frame, allowing the tissue to vaporize (ablate) without burning (carbonizing).

Glass Tube (DC)

Relies on direct current, making it slow to turn on and off. It primarily produces long pulses or continuous waves, which cause heat to diffuse into the surrounding tissue. This increases the risk of adjacent thermal damage (charring), leading to longer recovery times and higher complication risks.

Metal Tube (RF)

The RF electromagnetic field can be switched at extremely high speeds (nanoseconds or microseconds). This enables the generation of ultrashort, high-peak-power pulses (known as SuperPulse or UltraPulse). The energy in this pulse is sufficient to vaporize the target tissue, but the pulse ends before the heat can spread, resulting in precise tissue ablation with minimal residual thermal damage.

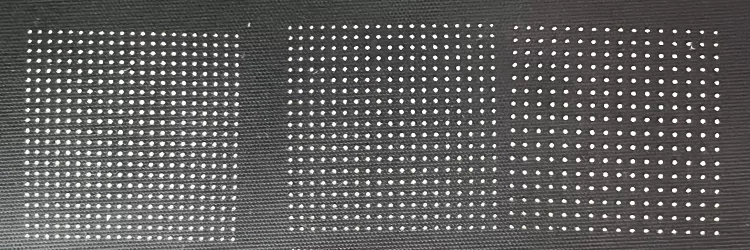

Precision for Fractional Resurfacing

When performing fractional CO2 resurfacing, the goal is to create thousands of microscopically precise columns of thermal damage on the skin.

The Metal RF Tube, thanks to its SuperPulse capability and excellent beam quality, ensures that every microscopic treatment spot has the same depth and width, achieving highly uniform results. This precision is crucial for treating acne scars, deep wrinkles, and enlarged pores.

Stability and Longevity

Sealed Structure: Metal tubes are built with a sealed structure, permanently containing the CO2 gas. Gas degradation is slow, leading to a much longer operational lifespan.

Thermal Control: The metal tube design offers far superior heat dissipation compared to glass, ensuring stable operating temperatures even at high power. This prevents the beam quality from drifting due to temperature fluctuations.